Sacrificial Protection

- Home

- What we do

- E-CATHODIC

- Sacrificial Protection

Sacrificial Protection using Aluminium and Zinc Anodes

provide cost effective solutions against corrosion. All anodes are cast from high grade material to ensure an even corrosion pattern, reliable electrical efficiency and long working life.

System Overview

Sacrificial Protection using Aluminium and Zinc Anodes provide cost effective solutions against corrosion.

Aluminium Alloy Anodes

Alalloy anodes are cast from special aluminium alloys developed by EICS. Suitably formulated for specific application, they are characterized by light weight, smooth corrosion pattern, high electrical capacity and stability. Fewer anodes may be used for a given installation compared with other materials and a substantially lower cost per installed system is achieved. Flexible Alalloy anode is extruded onto a mild steel core wire from a special patented aluminium alloy. The flexibility and light weight of this extruded anode, together with the method of clamping permits its use in applications where the use of cast block anodes may be difficult or uneconomical.

Product Range

The standard range of Alalloy anodes is listed overleaf. However, EICS specializes in designing and producing anodes to meet any individual requirement and make their own moulds to do so. Thereby, they ensure both the optimum solution to each problem and total control over the quality of the finished anodes.

Applications

Alalloy anodes are suitable for a wide variety of applications including the hulls and tanks of ships, fixed off-shore structure, semi submersibles, pipelines and jetties.

Materials

Different alloy formulations are available specially designed for different applications. Alalloy anodes are cast in alloys of aluminium and indium plus additions and have been developed specially for use in sea-water. The materials are very stable in driving potential and efficiency even in electrolytes of varying conductivity and temperature. In normal sea-water having resistivity of about 25 ohm cm, approximately 2500 ampere hours of current are provided by each kilogram of alloy which will maintain a potential of -1100mV when measured against a silver/silver chloride reference half cell.

Electrochemical Properties

Nominal Potential

-1100MV, AG,AGCL

Nominal Capacity

2500AH/KG

Zinc Alloy Anodes

Zincalloy anodes are cast from high grade zinc alloyed to ensure an even corrosion pattern, reliable electrical efficiency and long working life. Zincalloy anodes are cast from high grade zinc alloyed to ensure an even corrosion pattern, reliable electrical efficiency and long working life.

Product Range

The standard range of Alalloy anodes is listed overleaf. However, EICS specializes in designing and producing anodes to meet any individual requirement and make their own moulds to do so. Thereby, they ensure both the optimum solution to each problem and total control over the quality of the finished anodes.

Applications

Alalloy anodes are suitable for a wide varity of applications including the hulls and tanks of ships, fixed off-shore structure, semi submersibles, pipelines and jetties.

Materials

Different alloy formulations are available specially designed for different applications. Alalloy anodes are cast in alloys of aluminium and indium plus additions and have been developed specially for use in sea-water. The materials are very stable in driving potential and efficiency even in electrolytes of varying conductivity and temperature. In normal sea-water having resistivity of about 25 ohm cm, approximately 2500 ampere hours of current are provided by each kilogram of alloy which will maintain a potential of -1100mV when measured against a silver/silver chloride reference half cell.

Chemical Composition

Chemical Composition

Electrochemical Properties

Nominal Potential

-1.05V, AG/AGCL

Nominal Capacity

780 Ampere Hours per KG

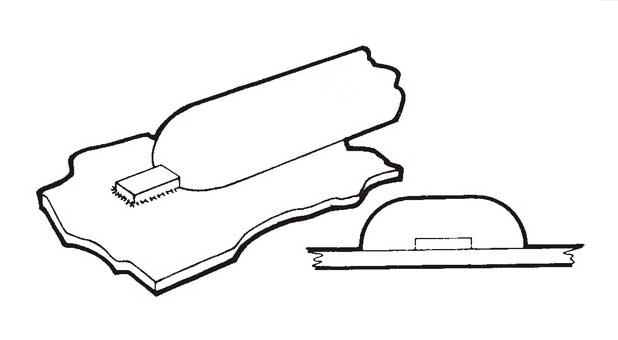

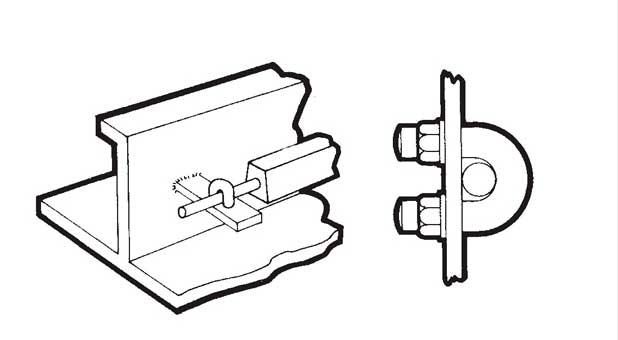

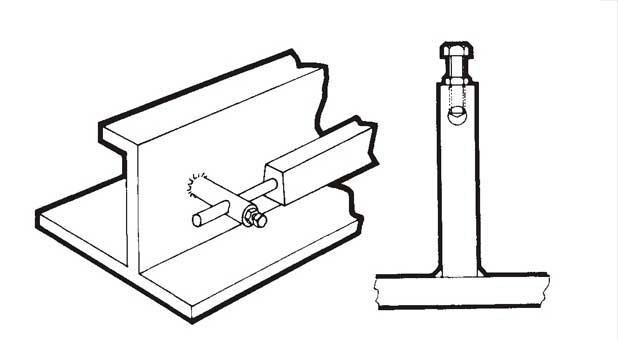

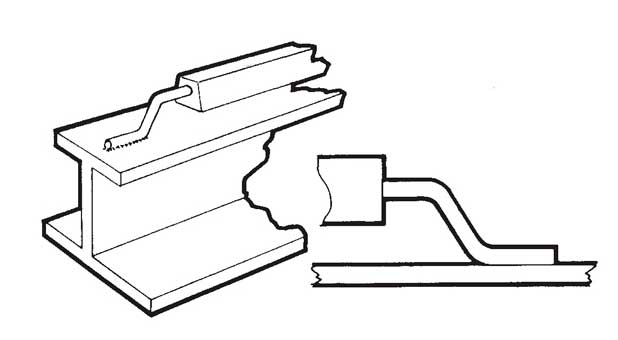

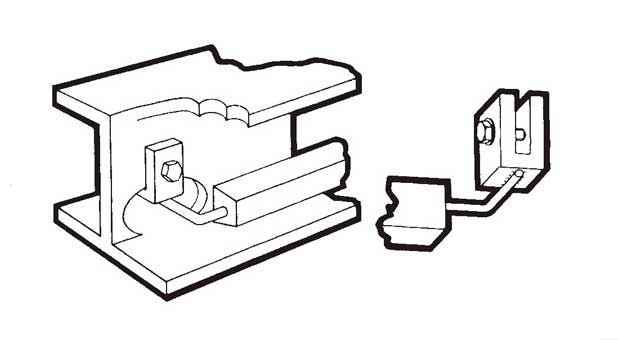

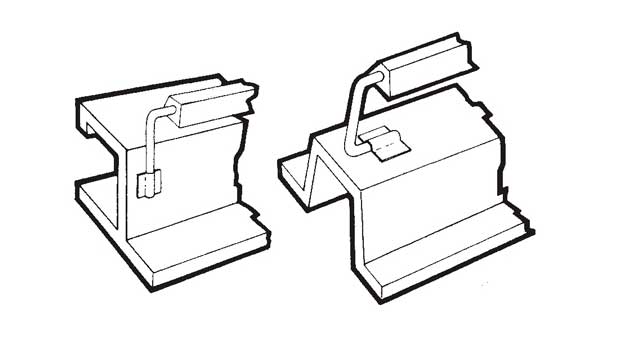

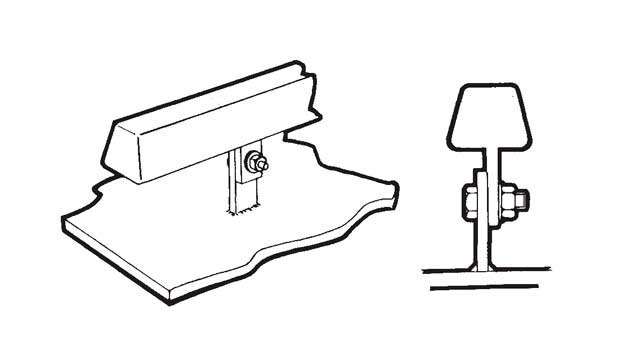

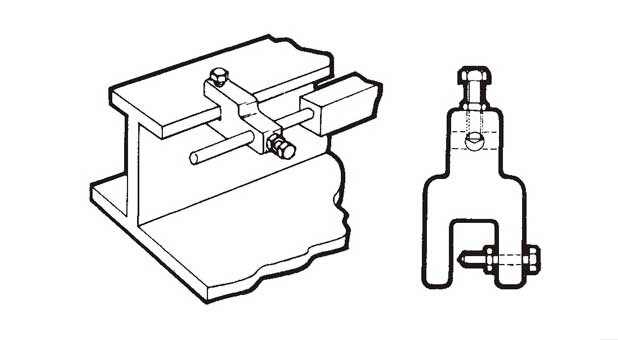

Typical Method of Attaching Anode for Hull and Tank Applications

External

U Bolt

E Type

Internal Z Type

Clamp Type

Single & Double Crankweld

Stand-Off Type

M Type

Quality Assurance

EICS is proudly

Made with passion

Our products are proudly made in Singapore and uses only reputable component renowned for their reliability. Our products are made to suit our customer requirements and is guaranteed to work and last!